Metal Castings: Step-by-Step Guide to Modern Casting Processes

Wiki Article

Light Weight Aluminum Castings Explained: Secret Perks and Solutions for Your Manufacturing Needs

Light weight aluminum spreadings play a substantial function in contemporary manufacturing. Their lightweight and sturdy nature makes them suitable for various applications. Industries such as aerospace and auto take advantage of their flexibility. Recognizing the benefits and the manufacturing procedure of light weight aluminum castings is vital. Additionally, picking the best service provider can influence quality and efficiency. What aspects should be taken into consideration when picking a light weight aluminum casting service? Checking out these elements exposes important understandings.Benefits of Aluminum Castings

Light weight aluminum castings use numerous advantages that make them a preferred option in various markets. Among the primary advantages is their lightweight nature, which considerably decreases shipping and managing expenses. Furthermore, aluminum displays outstanding rust resistance, making sure longevity and decreased upkeep for products made from this material. The convenience of aluminum permits intricate shapes and complex layouts, supplying manufacturers with greater flexibility in manufacturing.On top of that, light weight aluminum castings possess great thermal and electric conductivity, making them appropriate for a variety of applications requiring warm dissipation or electrical parts. The material also has a high strength-to-weight proportion, making it possible for the manufacturing of durable yet lightweight elements. Additionally, aluminum can be recycled without losing its homes, advertising sustainability in making procedures. In general, these benefits make light weight aluminum castings a reliable and trustworthy option for producers seeking top quality and performance in their items.

Applications of Aluminum Castings in Various Industries

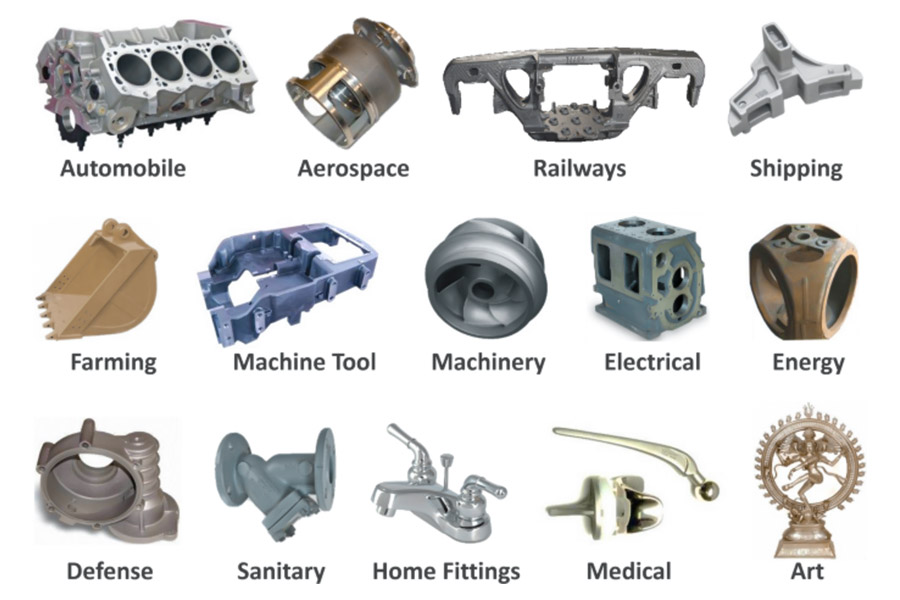

The advantages of aluminum spreadings make them highly looked for after across numerous industries, consisting of auto, aerospace, and consumer items. In the automobile field, they are used for engine blocks, transmission cases, and wheels as a result of their lightweight nature, which enhances gas effectiveness. Aerospace applications gain from light weight aluminum castings in structural parts and real estates, supplying toughness while lessening weight, vital for flight efficiency.

In customer products, light weight aluminum castings are utilized in products such as cookware and digital rooms, offering resilience and visual appeal (Aluminum Foundry). Additionally, the electrical market utilizes light weight aluminum spreadings for heat sinks and real estates, ensuring effective thermal administration. The versatility of light weight aluminum permits complex styles and complicated geometries, better broadening its applications. On the whole, the diverse energy of light weight aluminum castings emphasizes their significance in modern-day manufacturing, adding to advancement and performance throughout these vital sectors

The Manufacturing Refine of Light Weight Aluminum Castings

Casting aluminum entails a number of vital actions that transform raw steel right into accurate parts. The process starts with the melting of aluminum scrap or ingots in a heater, getting to temperatures around 1,200 ° F. When molten, the light weight aluminum is put right into a mold and mildew, which can be made from sand, steel, or ceramic, relying on the preferred specifications.After putting, the metal cools and strengthens, creating the shape of the mold and mildew (Aluminum Castings). The following step involves getting rid of the casting from the mold and mildew, which may call for extra strategies to ensure a smooth surface coating

Consequently, any kind of excess material or imperfections can be machined or ground off to achieve the final dimensions. Quality examinations are after that carried out to verify that the spreading satisfies required criteria. This careful procedure permits suppliers to produce parts that are light-weight, durable, and suitable for a vast array of applications.

Selecting the Right Light Weight Aluminum Spreading Service

When picking a light weight aluminum spreading solution, it is vital to consider numerous factors that can greatly influence the high quality and efficiency of the end product. Initially, the solution supplier's experience and competence in light weight aluminum casting play a vital function in guaranteeing top quality outcomes. Firms should evaluate the supplier's profile and previous tasks to gauge their capabilities.Additionally, assessing the modern technology and equipment used by the casting service is essential, as modern equipment you could try this out can boost accuracy and reduce preparations. An additional essential aspect is the capability to use personalized options tailored to details project needs, which can greatly boost item performance.

Moreover, interaction and consumer support must not be overlooked; a collaborative companion can help with smoother task implementation. Thinking go to website about cost-effectiveness without jeopardizing high quality is essential for making an informed decision. By meticulously weighing these aspects, suppliers can choose a casting solution that ideal meets their needs.

Future Fads in Light Weight Aluminum Casting Technology

As producers increasingly focus on top quality and effectiveness, innovations in aluminum casting modern technology are readied to transform the market. Emerging fads include the fostering of automation and robotics, which improve accuracy and reduce human mistake in casting procedures. Furthermore, the combination of expert system and machine understanding is expected to enhance production timetables and boost quality control.Sustainability stays a main focus, with technologies in recycling strategies permitting for a lot more effective reuse of aluminum scrap, thus lowering waste and energy consumption. Advanced simulation software is additionally obtaining traction, making it possible for engineers to design and predict casting performance before real manufacturing, minimizing costly errors.

The advancement of brand-new alloys and progressed casting techniques, such as 3D printing, will broaden the possibilities for lightweight yet long lasting parts. Together, these fads indicate a vibrant future for aluminum spreading, driven by technical developments that focus on sustainability, product, and effectiveness quality.

Often Asked Concerns

How Do Aluminum Castings Compare to Other Products?

What Are the Weight Limitations for Light Weight Aluminum Castings?

Weight constraints for light weight aluminum castings generally rely on the layout and application, yet they usually support lots linked here capacities varying from a few ounces to numerous tons. Certain restraints arise from factors like wall surface thickness and architectural stability.Can Light Weight Aluminum Castings Be Repaired After Manufacturing?

Aluminum spreadings can be repaired after manufacturing, making use of strategies such as welding or epoxy bonding. The usefulness of repairs depends on the level of damage and the specific residential or commercial properties of the aluminum alloy used.

What Finishes Are Available for Aluminum Castings?

Numerous finishes are offered for aluminum spreadings, consisting of anodizing, powder paint, covering, and polishing. These finishes boost look, provide deterioration resistance, and improve surface area longevity, accommodating varied aesthetic and useful needs in manufacturing applications.Exactly How Do Ecological Rules Affect Light Weight Aluminum Casting Processes?

Ecological guidelines considerably impact aluminum spreading processes by mandating more stringent discharges controls, encouraging reusing techniques, and promoting lasting products. These regulations force makers to adopt cleaner innovations and minimize their eco-friendly impact in manufacturing activities.

Report this wiki page